Understanding LCA is a crucial part of the sustainability claim for brands and manufacturers. Engineers at Fibrant explain how choosing EcoLactam® at the start of the manufacturing process can result in a lower carbon footprint of your nylon product.

A significant part of the sustainability claim for brands and manufacturers is the reduction of their carbon footprint. This is where understanding the LCA becomes crucial. Life Cycle Assessment, or LCA, is a methodology for assessing and quantifying the environmental impact of a product, process or a service, and identification of major contributors to environmental impact. Key categories include climate change (global warming), depletion of resources, water and land use, human health, biodiversity and ecotoxicity.

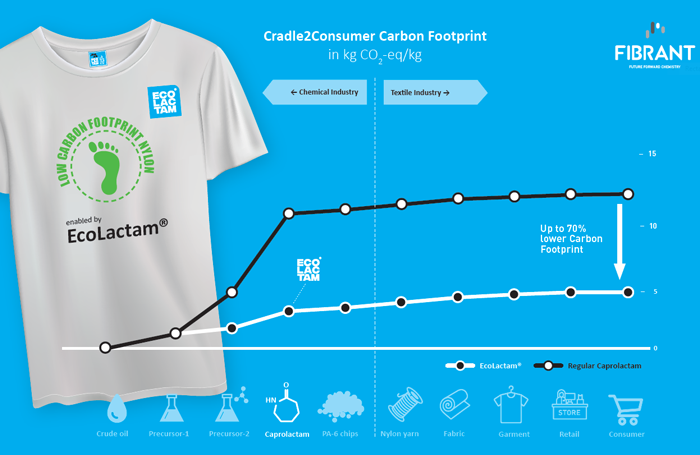

Amongst several other impact measures, the carbon footprint (CFP) is mostly used. The CFP calculates the amount of Greenhouse Gases (GHG) required to produce 1 kilogram of product and it is expressed in carbon dioxide (CO2) equivalents. The assessment considers a product's entire life cycle. The environmental impact of each step in the manufacturing process is calculated, beginning with the raw materials, and ending when the product is delivered to retail.

Consider a nylon shirt as an example: Like all other synthetic fibers, nylon is made from fossil resources that are converted into caprolactam, the building block to produce nylon-6 textile yarns. Fabrics are knitted from the yarns, garments are made from the fabric and then sold in retail. Each step of the process has its own carbon footprint. The amount that each step in that value chain contributes to the total - varies significantly. Caprolactam production has by far the greatest impact.

To address this issue, all brands and manufacturers should consider reducing their carbon footprint right from the beginning of production. Fibrant applies the LCA as a powerful method for measuring and tracking the environmental effects and primary contributions. Through a commitment to a sustainable, low-impact caprolactam production, Fibrant has delivered an optimal solution. EcoLactam® was developed by focusing on the process, feedstocks and utilities used. It deploys a process that has reduced caprolactam's carbon footprint up to 70% when compared to regular caprolactam. Technology and the feedstock selection directly lower the environmental results for EcoLactam®, and in parallel benefiting any nylon garments made with it. When produced on a large scale, it has a substantial and positive impact on the final product. The impact that counts!

As a final note: in most cases, the environmental impact of the product during use and after end-of-life disposal is not considered. However, it is critical to understand the nature of the product, its durability, and whether it can be recycled, to understand the total environmental impact. Always request an LCA to fully evaluate the effect a product will have during use, as well as after it is discarded.

Read more about the impact of EcoLactam®: https://www.fibrant52.com/en/products/ecolactam